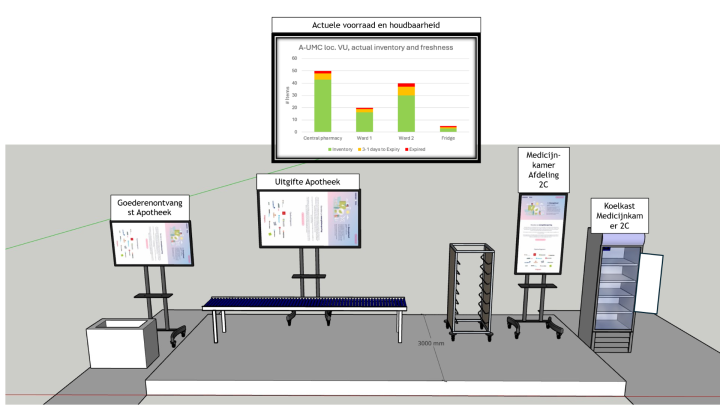

What we’re demonstrating today

You’ll see a complete RFID medication flow across four processes:

-

1) Goods receiving: scan tub check vs. order

Medication crates are placed in the RFID scan tub and automatically verified against the purchase order. Discrepancies are flagged instantly. -

2) Central pharmacy issue: conveyor belt registration

A medication crate is placed on the roller conveyor and registered as issued from the central pharmacy, creating real-time visibility of outbound flow. -

3) Ward inventory & usage: handheld counting (HH)

Zebra handhelds register ward stock, replenishments and consumption. Spot checks or cycle counts sync directly with the central inventory. -

4) Point-of-care storage: intelligent RFID medication fridge

The fridge automatically tracks stock, logs dispensing per user and monitors expiry with proactive alerts.

Want a walkthrough tailored to your setup? Ask us for a short demo slot or pilot outline.