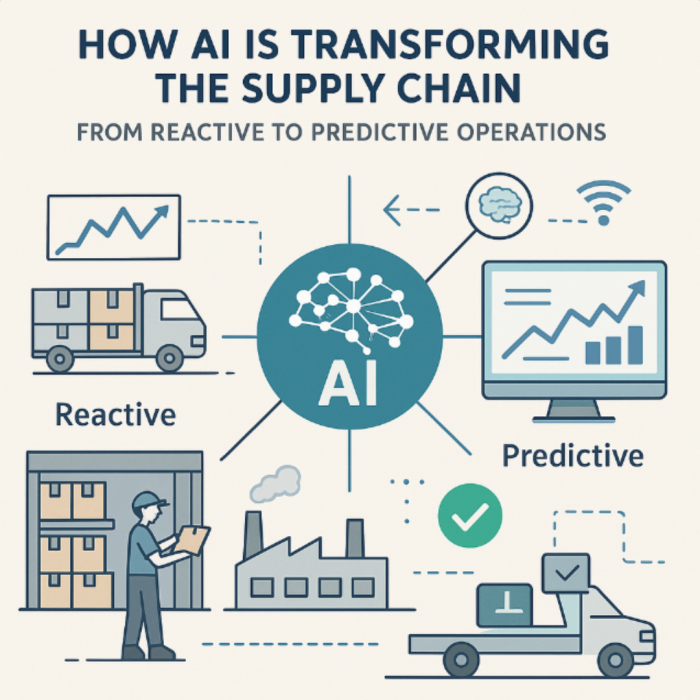

Supply chains are under more pressure than ever. Fluctuating demand, global disruptions and rising customer expectations have exposed the limits of traditional planning methods. Most organisations still operate reactively, adjusting when issues occur rather than anticipating them. Artificial Intelligence changes this dynamic. With machine learning, predictive analytics and smart automation supply chains become proactive, resilient and significantly more efficient.

At Mieloo and Alexander we see AI rapidly becoming the next major enabler in supply chain digitalisation. It elevates visibility tools such as RFID and real time tracking by turning raw data into actionable intelligence. Decisions become faster, more accurate and fully data driven.

Why AI Matters in Modern Supply Chain Management

AI in supply chain management provides a foundation for smarter, leaner and more predictable operations. Traditional planning relies heavily on manual data checks and historical assumptions which limits the ability to respond to volatility. AI systems can analyse millions of data points in real time, identify emerging patterns and recommend the best action before problems occur.

Organisations that adopt AI experience improvements such as:

- Better alignment between supply and demand

- Reduced operational costs through automation

- Faster decision making based on real time insights

- Lower inventory buffers and fewer stockouts

- Greater resilience against disruptions

These benefits arise because AI adds a predictive layer on top of existing digital infrastructure. Instead of reacting to exceptions companies can model future scenarios and prepare accordingly.

From Data to Prediction: The Power of Machine Learning

Machine learning plays a central role in predictive analytics for logistics. It identifies recurring patterns in demand, lead times, supplier behaviour and operational performance. Over time these models become more accurate and help logistics teams move from static planning to continuous optimisation.

Applications include:

- Predictive demand forecasting that adapts to seasonality, promotions or market dynamics

- Machine learning warehouse planning that optimises picking routes, staffing levels and storage allocation

- Predictive maintenance for equipment and reusable assets by analysing temperature, usage and condition data

- Transport forecasting that anticipates delays or bottlenecks based on live network conditions

Organisations with strong data foundations, such as RFID enabled item level visibility, get the most value from AI. When data is accurate and complete models perform better which accelerates the impact of AI driven optimisation.

AI Driven Logistics: Smarter, Faster, More Sustainable

AI strengthens logistics execution by improving accuracy and reducing waste. With predictive analytics logistics networks can automatically adjust based on expected demand or disruptions. Warehouses become more efficient as picking strategies and replenishment tasks are continuously optimised by machine learning.

Examples of AI driven improvements include:

- Reduced transport movements thanks to optimised routing

- Lower energy consumption in storage environments

- Automated exception handling instead of manual troubleshooting

- Real time replenishment signals triggered by accurate consumption data

These improvements not only reduce cost but also support sustainability goals by minimising waste and unnecessary resource use.

Smart Supply Chain Automation: When AI and RFID Work Together

While AI provides predictions and recommendations real time data capture ensures that the physical world and digital operations stay aligned. RFID, sensors and IoT devices continuously feed data into AI models which strengthens accuracy and responsiveness.

This combination enables:

- Automated inventory updates

- Real time asset tracking

- Intelligent restocking and fulfilment

- Continuous monitoring of critical flows

Smart supply chain automation arises when AI and operational technology work as one ecosystem. It is the next step in digital transformation logistics and a key driver of supply chain optimisation for the coming decade.

How to Get Started with AI in the Supply Chain

AI adoption does not need to be complex. Organisations see the most impact when they start with focused use cases that deliver measurable value. Common starting points include demand forecasting, predictive maintenance or warehouse planning.

Successful AI programmes share several characteristics:

- A solid data foundation supported by automated data capture

- Clear operational objectives

- A scalable digital architecture

- Cross functional collaboration between supply chain, IT and operations

By building step by step companies quickly move from pilot projects to enterprise wide optimisation.

Why Companies Choose Mieloo and Alexander

With 25 years of expertise in supply chain visibility, automation and data driven solutions we support organisations in accelerating their AI journey. Our work with RFID, sensors, hardware integration and real time software platforms provides the high quality data foundation AI needs to perform.

We help companies improve accuracy, streamline operations and build resilient predictive supply chains that are ready for the future.