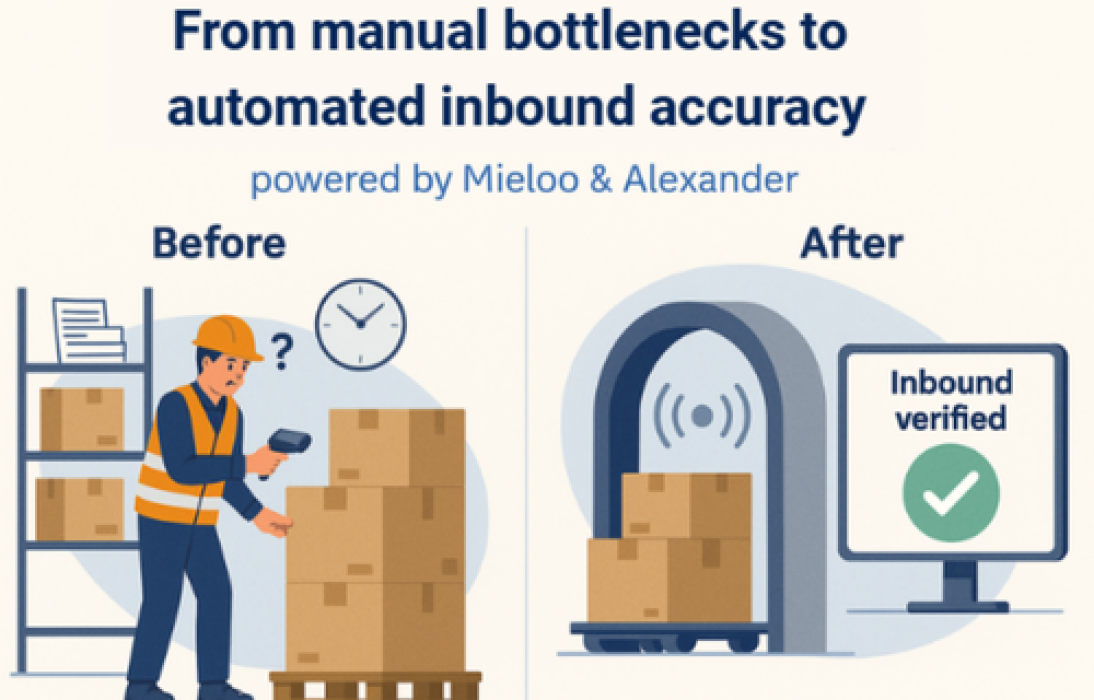

The inbound accuracy challenge

Every logistics manager knows the problem: shipments arrive with discrepancies. Pallets may be missing items, cartons get miscounted, or paperwork doesn’t match what’s physically delivered. These inbound errors create bottlenecks, delay outbound flows, and inflate costs.

Traditional manual receiving methods, scanning individual barcodes or counting by hand, are not only slow, they’re also error-prone. The result: inaccurate inventory, rework in the warehouse, and frustrated customers down the line.

Why inbound accuracy matters

Inbound errors ripple through the entire supply chain:

- Inaccurate stock levels lead to fulfillment mistakes

- Delays at the dock slow down put-away and outbound shipments

- Increased labor costs from manual double-checking

- Reduced customer satisfaction due to late or incomplete orders

Improving inbound accuracy is therefore not just an operational fix, but a competitive necessity.

Mieloo & Alexander’s solution: RFID tunnels

At Mieloo & Alexander, we help logistics operations automate bulk receiving with RFID tunnels. Instead of scanning every item individually, pallets and cartons move through an RFID tunnel where tags are read in seconds.

- Read hundreds of items simultaneously with near-100% accuracy

- Validate shipments in real time against advance shipping notices (ASN)

- Cut receiving time by up to 80% compared to manual barcode scanning

- Flag discrepancies instantly, before goods enter stock

- Feed accurate data directly into the warehouse management system (WMS)

Real-world impact

Clients using our RFID tunnels have seen:

- A reduction of up to 90% in inbound errors

- Faster throughput at docks, freeing capacity for growth

- Accurate real-time visibility of inbound stock across multiple sites

- Strong ROI within the first year of implementation

Why Mieloo & Alexander?

With over 25 years of RFID expertise, Mieloo & Alexander delivers turnkey inbound automation projects, from RFID hardware solutions to asset tracking. We know how to balance technology, processes, and people to ensure fast adoption and measurable results.