Cocoa, coffee and rubber are among the highest-risk commodities when it comes to deforestation and human rights violations. For companies sourcing these materials, supply chain transparency is no longer optional, it’s a regulatory requirement under the EU Deforestation Regulation (EUDR).

Building a sustainable supply chain starts with knowing where your raw materials come from, and being able to prove it.

The challenge of traceability in high-risk commodities

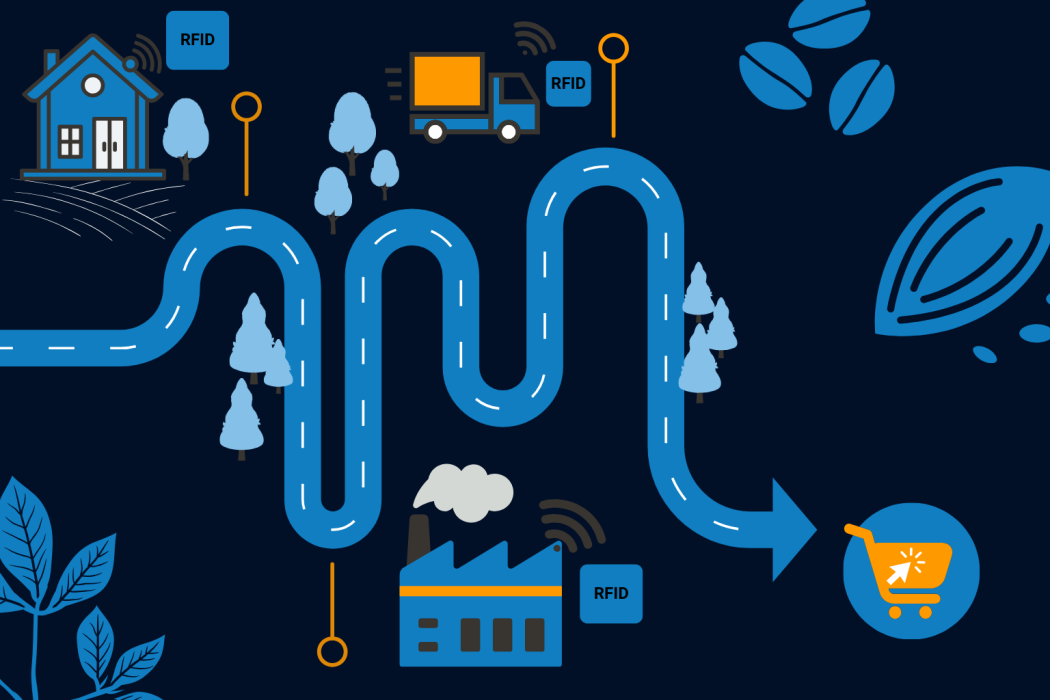

In complex global supply chains, products often pass through many hands before reaching the end customer. Without accurate, verifiable data about origin, it’s nearly impossible to guarantee deforestation-free sourcing. Traditional methods like batch documentation or paper certificates are prone to error and fraud.

How RFID and IoT improve sustainable supply chains

RFID technology, combined with IoT sensors, offers a way to track raw materials from source to shelf. By tagging batches at origin, for example, at a cocoa co-op or rubber plantation, companies can follow movement through transport, processing and packaging. Data is stored digitally and can be linked to sustainability certifications and geolocation data.

IoT sensors add another layer by monitoring conditions like temperature, humidity or handling quality during transport. The result: a sustainable supply chain with real-time, verifiable data, compliant with EUDR and future-ready.

Benefits of RFID and IoT for compliance

- Proof of origin and chain-of-custody

- Automated linkage to sustainability certificates

- Real-time alerts for handling violations

- Centralised data for reporting and auditing

- Stronger supplier accountability

Mieloo & Alexander’s role

We help companies implement RFID-based traceability solutions that integrate with ERP and logistics systems. Our approach is scalable, field-tested and built to support compliance in sectors dealing with complex, high-risk sourcing.